The Evolution of Coil Coatings and Paint Systems for Metal

Numerous finishes redefine what is possible for fabricators and designers

There are various options for applying paint to metal. In the field it is common to see spray or brush applications; in the factory, you can spray, powder coat or coil coat. However, when it comes to the performance requirements of today’s metal architecture, products like metal composite materials almost exclusively use the coil coating process to apply finishes that look practically flawless and can last.

Coil coating is the method by which a metal coil is coated in a continuous process prior to fabrication. The metal coil is brought through an uncoiler, a line-loading accumulator, processed and painted according to requirements, brought through a finish line exit accumulator and then rewound on a recoiler. These coils are finished and cured in a continuous process. Though traditionally used for aluminum substrates, this procedure can be applied to other metals, such as steel.

According to the National Coil Coating Association, prepainted metal “holds up better over time than post-painted surfaces ...” With robust quality assurance programs, coil-coated metal has a clear advantage with regards to consistency. Continuous manufacturing also allows for lower costs and greener manufacturing with reduced waste, increased efficiency, and the collection of VOCs.

Methods of Coating

Application of paint to metal has moved beyond spray systems, which are now more typical in a single-sheet batch process. Continuous coil coating manufacturing utilizes either a roll coating or a die coating method. Reverse roll coating, common in metal manufacturing, applies paint with two rolls running in opposite directions. A metering roll loads and transfers paint to an applicator roll, which then applies the coating to the substrate. This allows for good control over the paint thickness but leaves the panel susceptible to “roping” marks, striations that form at the edges of the brush resembling a ship’s wake.

Die coating is a precision coil coating process that maintains the advantages of high-volume, continuous process coating, but with even greater paint control. Paint is applied directly to the substrate through a slot die extrusion system.

Paint thickness is meticulously controlled in a single, seamless application. Both the paint system and the coil require exacting quality standards in the die coating process. The result is the smoothest coating possible with the added bonus of being more sustainable because of the reduction in waste.

Paint Systems

Paint systems evolved over the years as the industry began to require more from finishes than polyester and urethane paints could provide. The only paint systems capable of meeting the most commonly referenced architectural performance specifications laid out in AAMA 2605 are fluoropolymers. The unique chemical composition provides exceptional weatherability and durability.

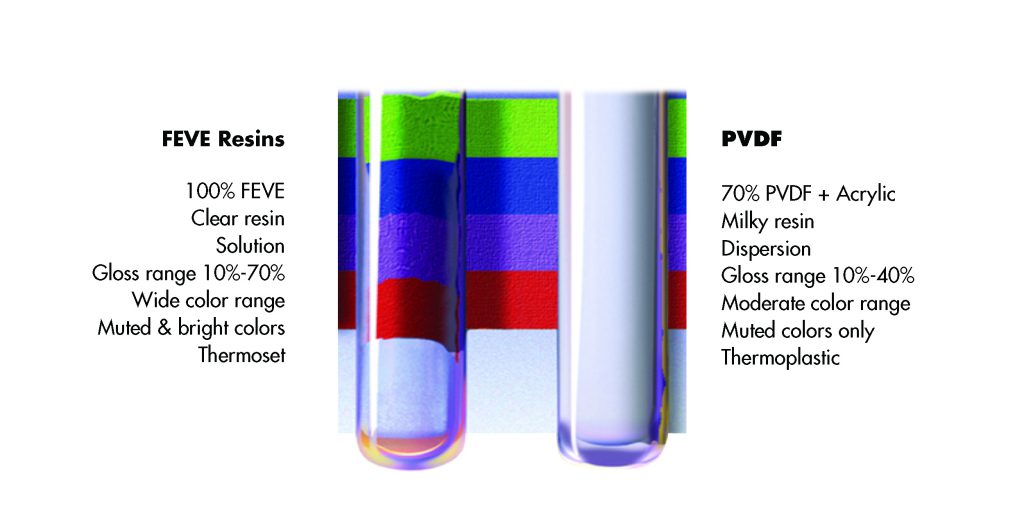

The first generation of fluoropolymer paint introduced in 1948 was polyvinylidene fluoride (PVDF). This paint system requires an additional acrylic resin to formulate PVDF into a coating, with the highest performance dispersion rate at 70 percent PVDF and 30 percent acrylic resin. As the ratio of PDVF to acrylic drops, so does the paint performance. The paint is thermoplastic, melting at high temperatures, however no chemical cross-linking occurs. This makes PVDF susceptible to remelt. PVDF is a relatively low-gloss finish. As measured by a 60-degree gloss meter, it is limited to a 30 to 40 range. Because of the added acrylic, color palettes are limited and bright colors can be a challenge.

The second generation of fluoropolymer paint introduced in 1982 is fluoroethylene-vinyl ether (FEVE). This paint system is thermoset, chemically cross-linking the fluorocarbon components so that under high pressure and temperature they will not remelt. FEVE is a clear resin, allowing for brighter and more vibrant finishes and has a smooth surface capable of a gloss rate as high as 70.

Advancements in coil coating and paint systems have enabled a nearly limitless palette of finishes that can last for decades. The introduction of metal composite material (MCM) into the architectural landscape was another revolutionary innovation. MCM is versatile and easy to fabricate into complex forms without the weight or other issues, such as oil canning found in solid plate metal. Over the last 40 years, these advancements have radically redefined what is possible for fabricators and designers.

Jim Moses is the technical services manager at Mitsubishi Chemical Composites America’s ALPOLIC MCM division, Chesapeake, Va. He has more than 40 years in the construction manufacturing, engineering and operations field, and is an active member of industry associations.

This article was featured in Metal Construction News.