ALPOLIC® Brake Metal offers a complement to our Aluminum Composite Material products, giving fabricators the ability to form roof caps, flashing, fascia trim, accents and other complex forms using a sheet metal brake. This material is finished with Lumiflon® FEVE fluoropolymer resin in many of our most popular 4mm architectural stock colors and select specialty colors. Custom colors are also available when aluminum Brake Metal and matching ACM panels are ordered together and finished in the same special run.

Why ALPOLIC® Brake Metal

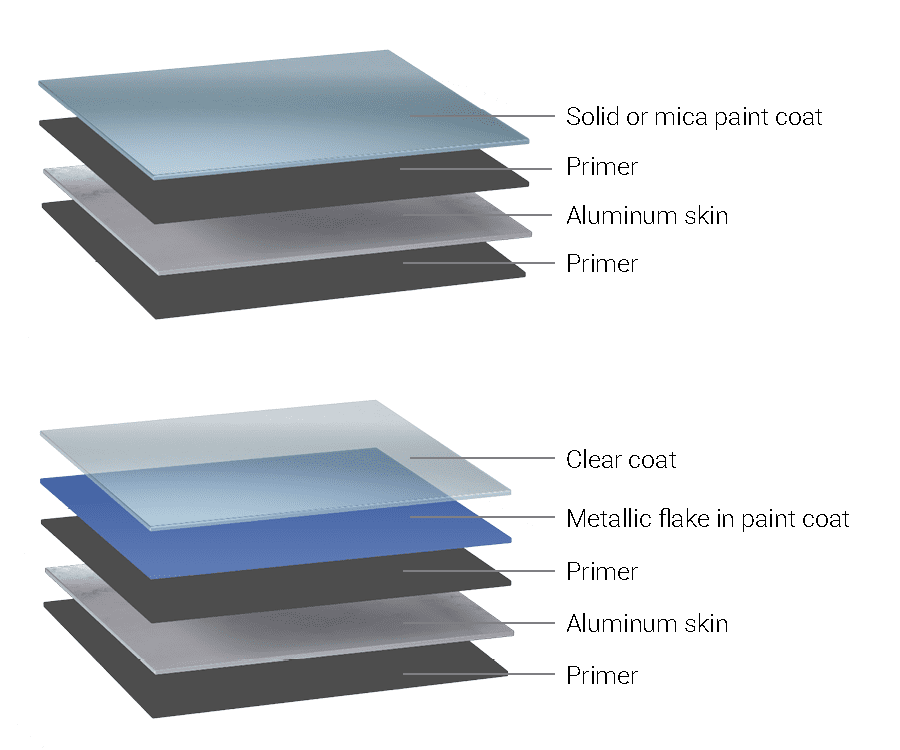

When using an ordinary cladding system, it can be difficult to get an acceptable color match for roof caps, flashing, fascia trim and other complex forms that are specified for the project. ALPOLIC® Brake Metal provides a perfect match for many of our most popular ACM panel finishes, including solid colors, micas and metallics. Custom panel colors can also be matched when the aluminum Brake Metal material is included in the custom panel order.

Using ALPOLIC® Brake Metal

ALPOLIC® Brake Metal is stocked in 48″ x 120″ flat panels, 0.032″ thick. Panels are coil-coated with our Lumiflon® FEVE fluoropolymer resin in Valflon® finishes by Sherwin-Williams, providing the same remarkable color vibrancy and durability as the matching composite panels. The minimum order for standard colors is five panels. Custom colors must be ordered together with a minimum of 2,000 square feet of matching custom-finished panels.

Aluminum Brake Metal can be easily fabricated to create virtually any form an experienced sheet metal brake operator can make. As with our composite panels, each Brake Metal sheet is protected by a clear film, which should be left in place during fabrication and removed soon after installation.